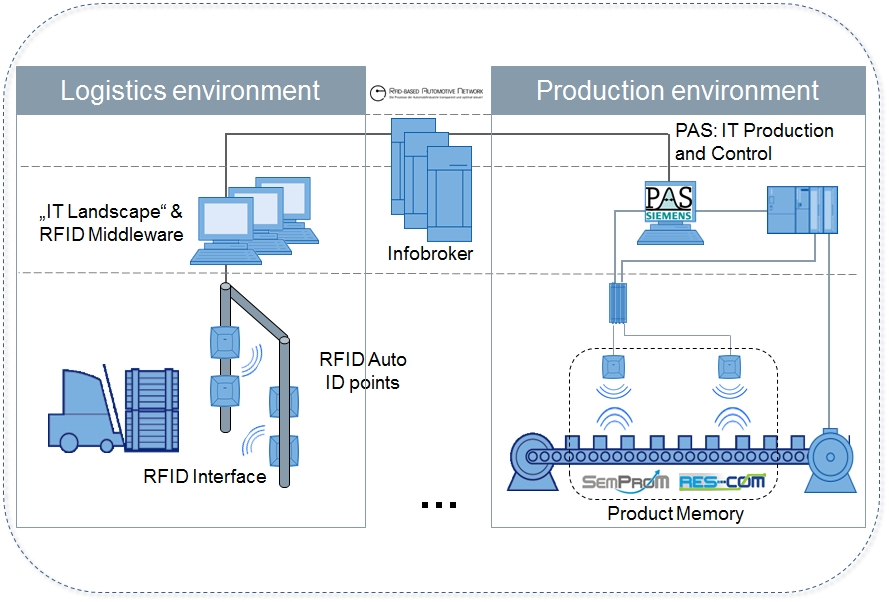

Industry 4.0 factories become more and more complex with increased maintenance costs. Reduced costs by cyber-physical (CP) controllers ensure the commercialization of the results. We implement multi-adaptive CP controllers in these domains: industrial robot arms, car manufacturing, steel industry, and assembly lines in general. The main objective is to implement such controllers for the application domains and let the industry partners provide feedback about the cost reduction potential. This will be realized by integrating the Siemens cPAS platform which uniquely combines cross-enterprise event management with digital product memory technology and Smart Object Virtualization. The tight cooperation of automation and IT vendors should enable sustainable business models supporting the European manufacturing sector to manage its increasingly complex, inter-organisational production networks and align them efficiently with global supply chains. The individual components will be ready as products or as input for product development. Innovation is supported by evaluated business models and concrete examples for customer business cases. (Click to enlarge architecture descriptions.)

The activity consists of three main milestones and corresponding catalyst tasks:

- CPS Knowledge engineering. Understanding the formal requirements of application cases and their formalization;

- Implementation of Software modules and tuning formal models and rules to test scenarios of anomaly detection in physical environments. This includes functional programming with learning capacity, and ontology creation/manipulation/extension via a semantic portal infrastructure;

- Transfer of modules in industrial settings, first evaluations, and business modelling.